|

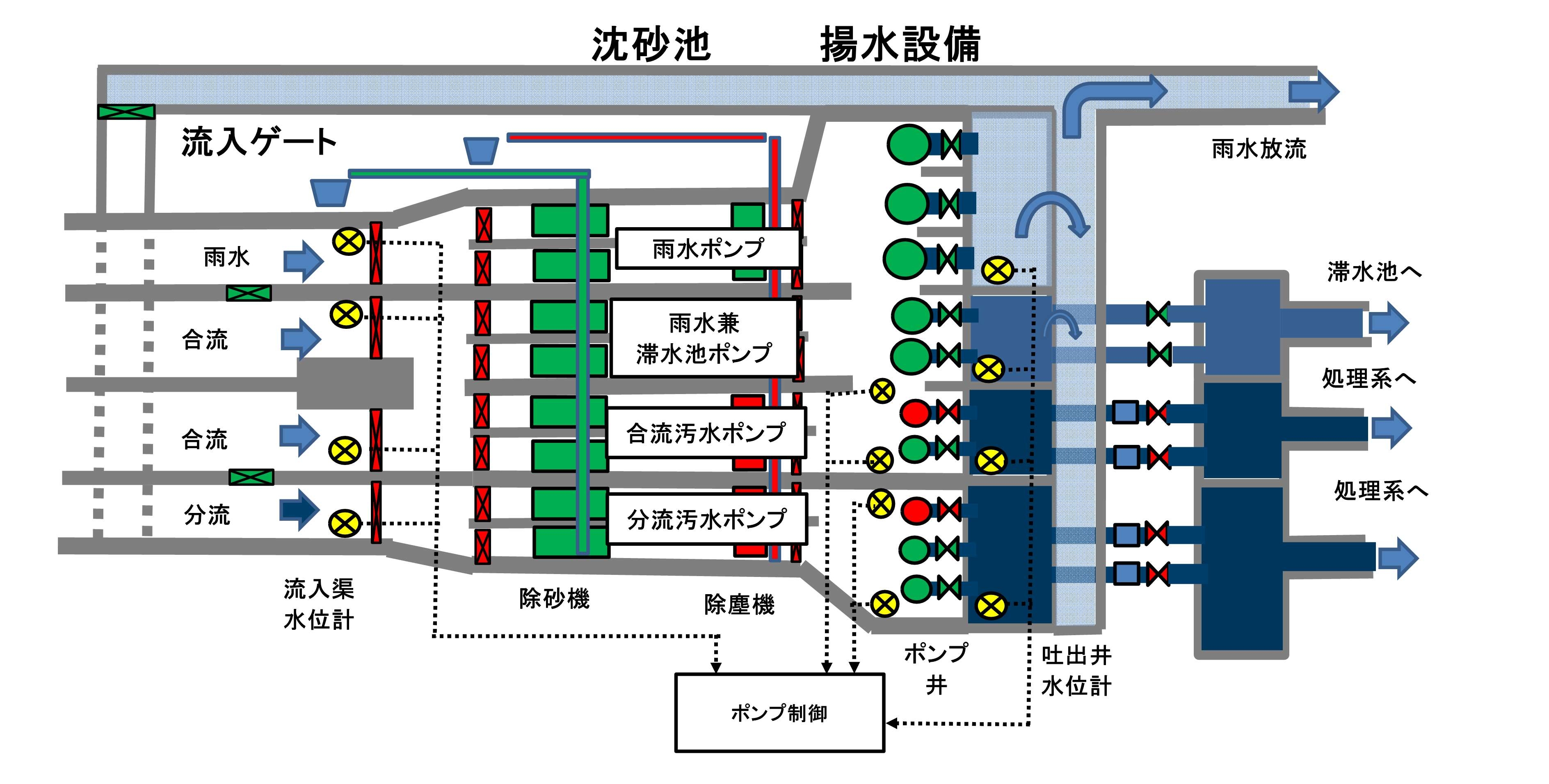

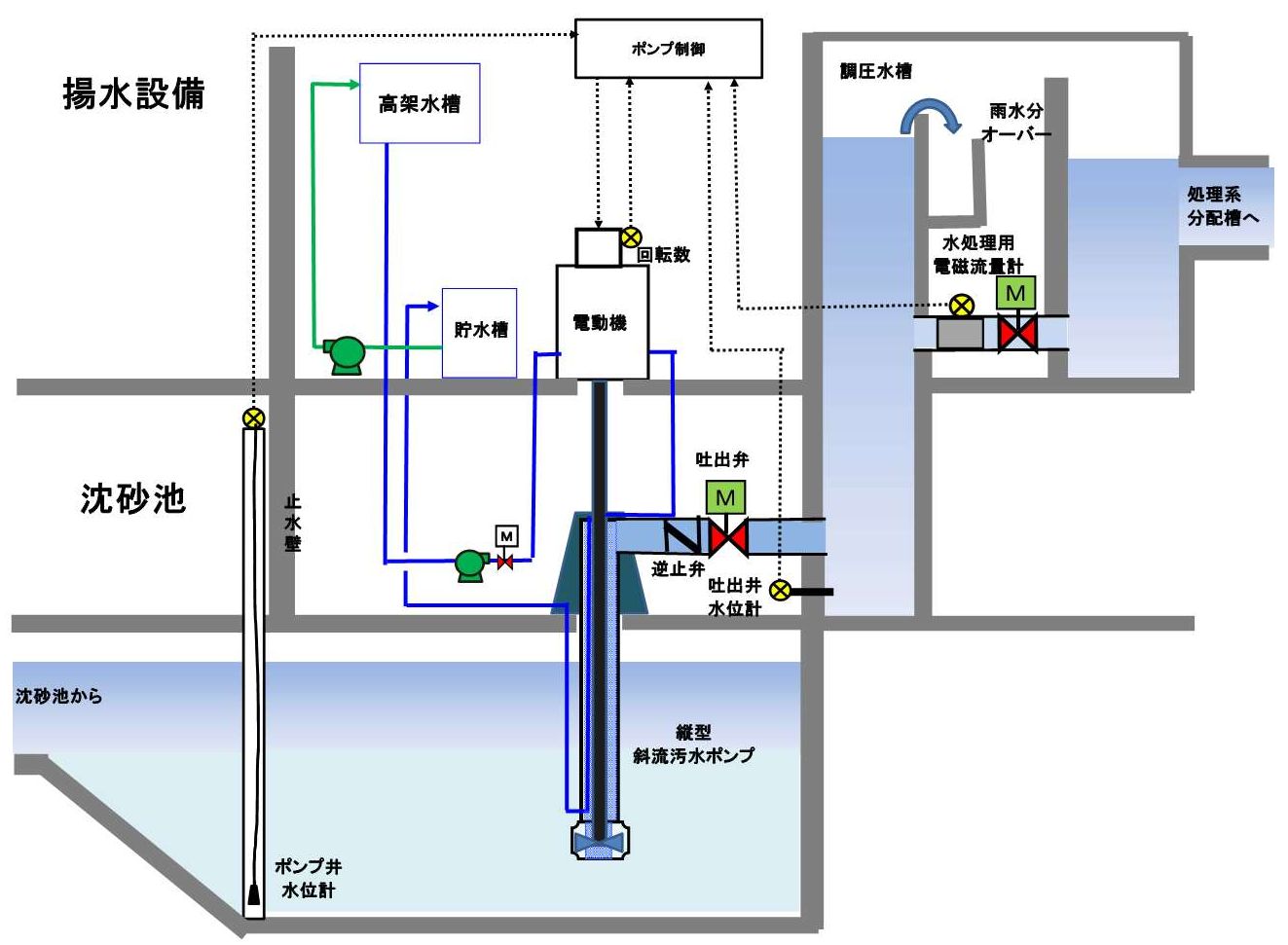

Pumping equipment

1 Control of diversion and confluence sewage pumps , rainwater pumps

Pump control is an important mechanism in pumping equipment. It is important to understand its strengths

and weaknesses for stable operation. Generally, there are the following control measures.

(1) ON - OFF control

(2) Constant flow rate control

(3) Water level flow rate control

(4) Constant water level control (including improved version)

(5) Predictive control (various names)

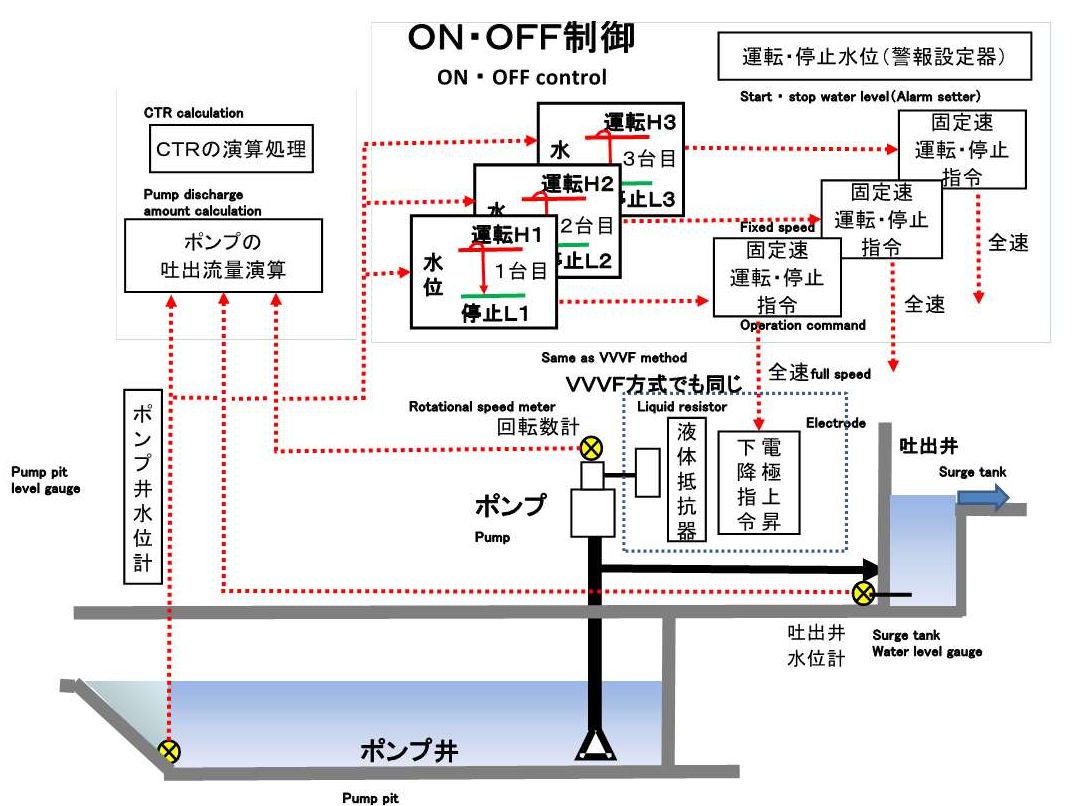

(1)ON - OFF control

Set the operating water level and stop water level of the pump.

If there are multiple pumps, shift the operating range according to the pump well water level

so that stable operation can be achieved as a whole. Set the smaller pump to run faster.

The pump whose rotation speed can be changed is also operated at full speed.

Therefore, since it is a backup operation assuming a CTR failure, it is configured

with a hard sequence such as an alarm setter.

(2)Constant flow rate control

The number of pumps is determined by the preset target flow rate, and the speed is controlled by

PI control from the deviation between this target discharge flow rate and the actual pump discharge flow rate.

In normal operation, it is necessary to absorb fluctuations in the inflow amount by fluctuations in the sand

basin and water level of the main line, so it is necessary to consider the storage capacity and respond to

fluctuations in the inflow amount sequentially. It is operated as a short-term operation change such as.

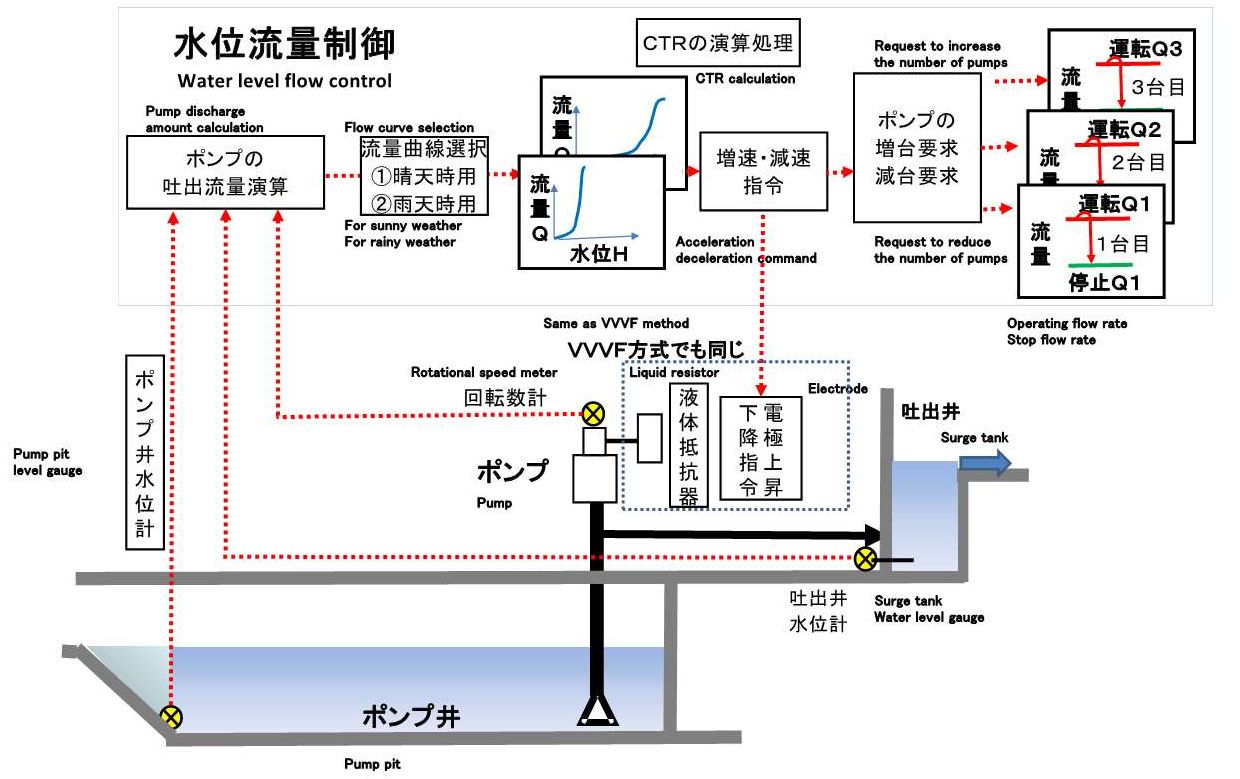

(3) Water level flow rate control

Set the water level and flow rate curve, and adjust the flow rate of the pump according to this curve.

In the case of a merging pump, two or more setting curves are required because the inflow amount fluctuates

significantly between sunny and rainy weather. When setting the curve, especially depending on the rainfall

situation, it is necessary to carry out several verification tests.

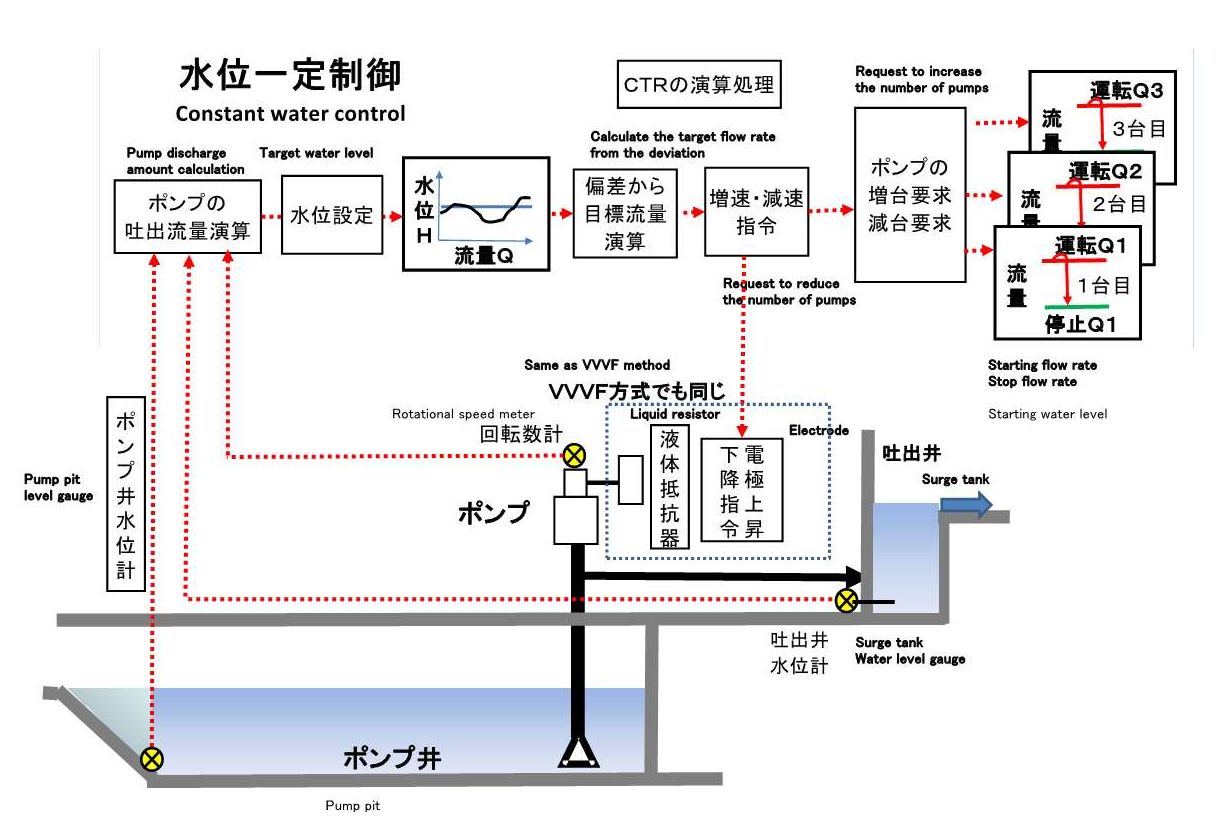

(4)Constant water level control

The target discharge flow rate is calculated from the deviation between the preset water level target value

and the pump well water level, the number of pumps is determined by the target discharge flow rate, and the

speed is controlled by PI control from this target discharge flow rate and the actual pump discharge flow rate

deviation. I will drive. Since the water level does not fluctuate, the discharge flow rate fluctuates more.

Therefore, it seems unsuitable for sewage treatment.

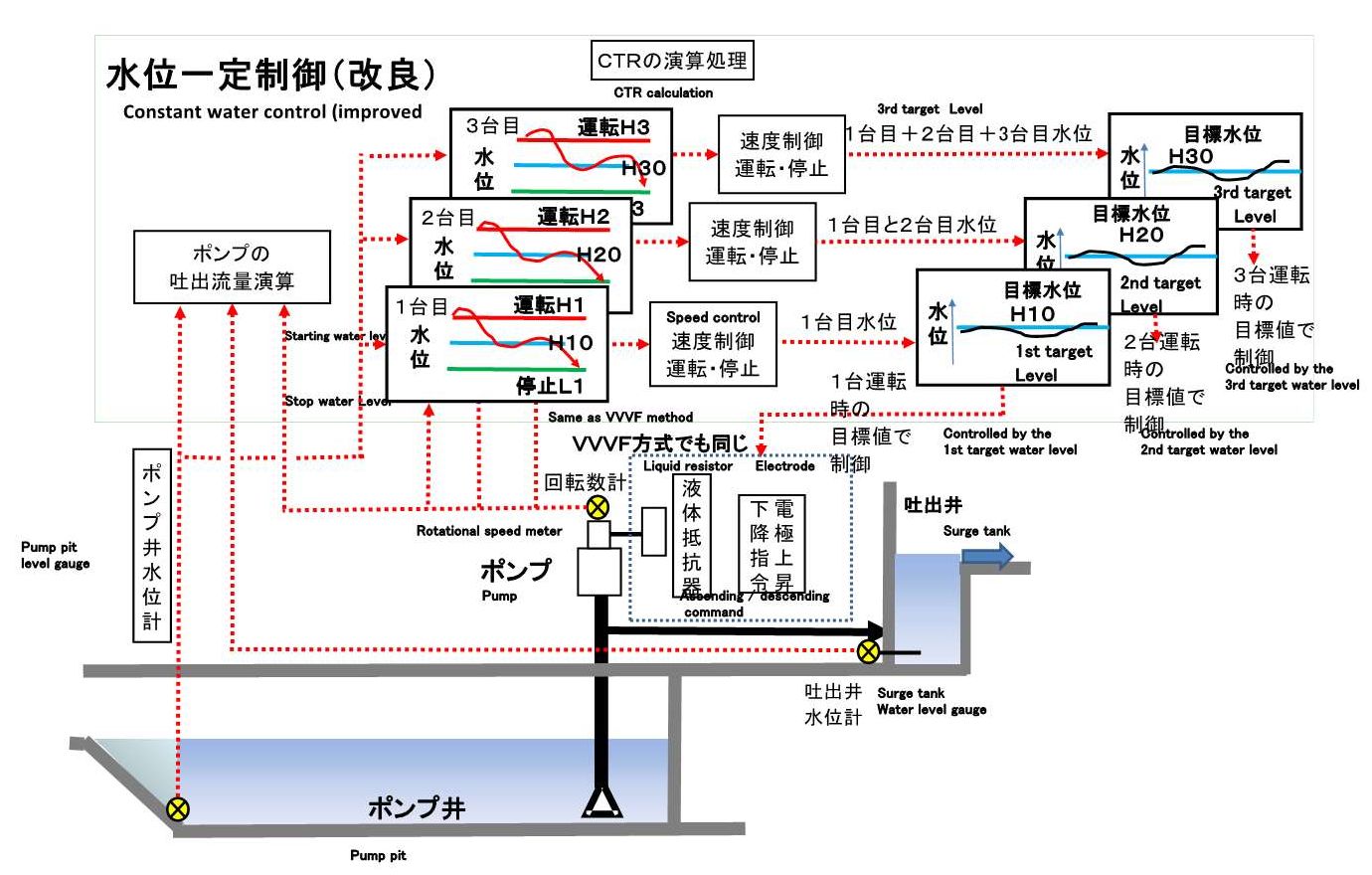

1) Constant water level control (improvement)

Normally, the constant water level control sets only one water level for multiple pumps. Therefore,

regardless of the pump capacity, the operation will be the same water level, so the operating water level

will be set according to the large pump, and the pump well water level will always be maintained high.

In addition, since the number of units is controlled by converting the water level deviation to the target

flow rate, a calculation delay will occur. To improve this, we will make it possible to set the target water

level according to the operating unit.

The target water level during operation is

① When the first unit is in operation, the target water level of the first unit

② When operating the second unit, the target water level of the second unit (first unit + second unit)

③ The target water level of the 3rd unit is the target water level of the 3 pumps (1st unit + 2nd unit + 3rd unit)

It will be.

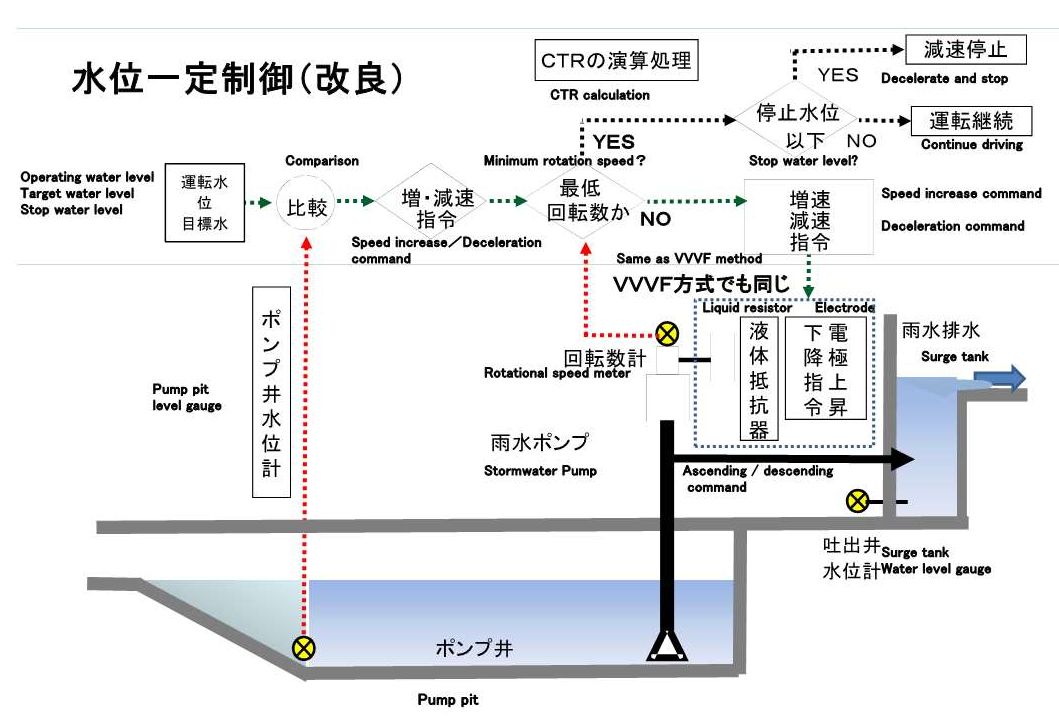

2) Features of the constant water level control (Improvement) version

The improved version of constant water level control does not require flow rate calculation for control calculation.

The flow rate calculation module cannot cope with the recent increase in guerrilla rainstorms due to response delays

and other factors.

With this method, when the water level deviates from the target, the number of revolutions can be increased or decreased

to increase the tracking to the inherent responsiveness of the liquid resistor. In addition, the speed of the operating

unit is constantly controlled, so it is as if one large pump is operating. This makes it resistant to fluctuations such

as a sudden rise in water level (increase in flow rate) and a decrease in water level (decrease).

However, if the rotation speed is changed too sensitively to the water level deviation, the liquid resistor will be affected.

Liquid resistors are unique to each manufacturer, and the electric oil operation type (manufactured by Hitachi) is not

particularly affected, but the electric speed reducer method (manufactured by Mitsubishi / Toshiba) and the pneumatic method

(manufactured by Nishihara Environment) prevent inching for adjustment. It is necessary to devise such as. In addition,

I think that you can get a sufficient response without raising the response to that extent.

The high-voltage VVVF method that has come to be used in recent years is considered to be about the same as the electric

oil operation method.

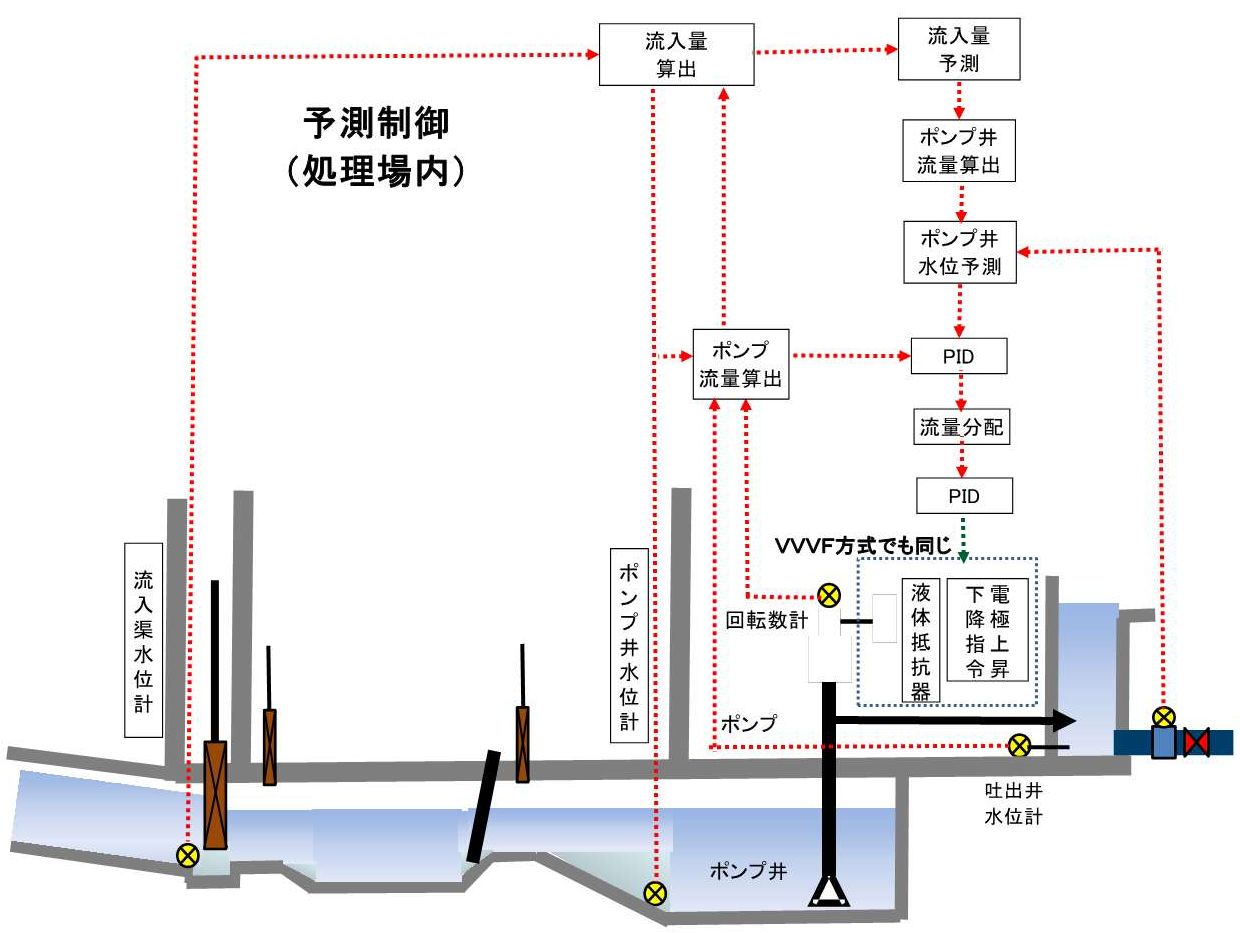

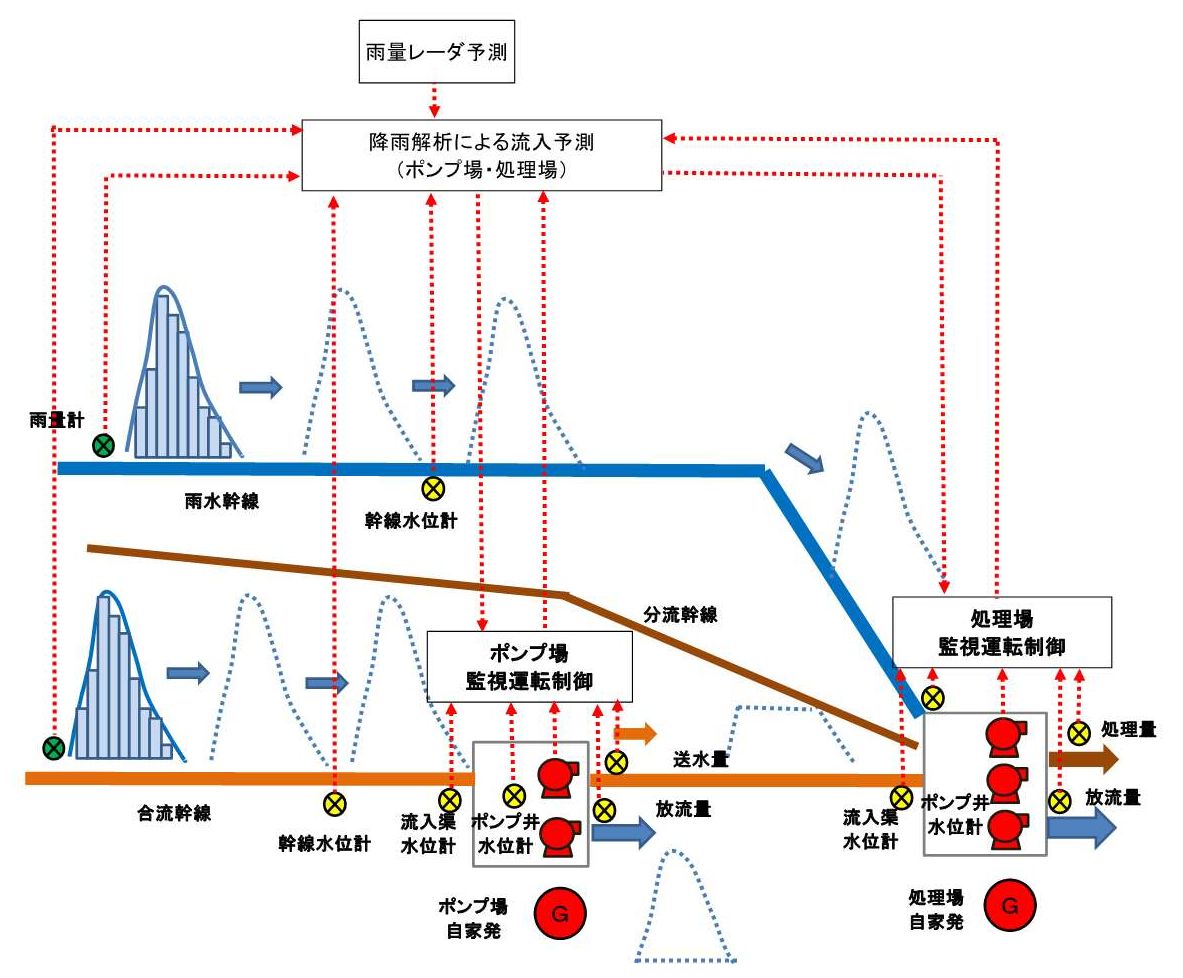

(5) Predictive control

Control that has good naming but is difficult to realize. If it works well, it gives us a

feeling that it may be a countermeasure against the recent heavy rains of guerrillas. Various

methods are possible.

1) The pump is controlled by predicting the inflow amount from the water level of the inflow culvert

and the water level fluctuation (storage amount) of the pump well.

The inflow flow rate is calculated, the number of pumps is controlled, and the pioneering operation of privately-generated equipment is performed.

Forecasting is done based on the measured values in the processing plant, so the forecasting range is limited.

2) The pump is controlled by predicting the inflow amount from rainfall and water level fluctuation

of the main line linked with the main line inflow monitoring control.

Inflow time and inflow are predicted from wide-area rain gauges, trunk water level gauges, and rainfall radars,

and pumping stations, treatment plant pumps, and self-generated operations are performed. In addition, the inundation

range prediction at the time of pump failure is displayed on the monitoring screen.

Either way, the more sensors there are, the more complicated it becomes, and the disadvantage is

that the number of weak points increases.

The case that was realized is unconfirmed.

(6)Requirements for control

① Instrumentation 1 Pump well water level gauge, discharge well water level gauge

② Transmission 1 Pump that can control the speed when controlling the speed

③ Instrumentation 2 Pump rotation speed meter for displacement calculation

④ Transmission 2 When predictive control is performed, the number of transmissions will

increase depending on the scale.

2 Evaluation of each control

1) ON / OFF control

Advantages

①Easy to understand the startup timing.

②The control operation is easy to understand due to the hard sequence.

③Operation is possible even when the CTR fails

Disadvantages

①Since the variable speed pump is also operated at a fixed speed, it is easy to repeatedly

start and stop the pump. Depending on the rainfall situation, there may be unstable factors

such as start-up timing including the operation of privately-owned equipment.

(2) Constant flow rate control

Advantages

① It is easy to adjust the flow rate during plant operation such as construction.

Disadvantages

① If the inflow fluctuation is large, manual intervention is required.

(3) Water level flow rate control

Advantages

①Water can be stably sent to the treatment system with little fluctuation in flow rate due to

operation stoppage.

Disadvantages

①It is necessary to prepare several types of water level flow curves for rainfall. Also, it

is necessary to devise to switch automatically instead of manually.

②Depending on how the number of units is controlled, the response may often be slow.

(4) Improved version of constant water level control

Since there are many disadvantages to normal water level constant control, it will be evaluated

as an improved version. Advantages

①Since the water level fluctuation range is drained with respect to the inflow amount, stable

operation is possible against guerrilla rainstorms.

②It is easy to understand the start / stop water level and predict failures.

Disadvantages

①Since the fluctuation range is large with respect to the inflow amount, it is not suitable

for sending water to the treatment system.

Therefore, it is more useful for rainwater pumps than sewage pumps for splitting and merging.

②Depending on the setting of the minimum rotation speed, it may not stop easily following the

water level. In this case, change the setting value of the minimum rotation speed to a higher value.

(5) Predictive control

No matter how much information is entered, the results will not follow unless the equipment operated

by control changes.

①The trunk line is shared with other pumping stations, stormwater reservoirs,

and storage trunk lines.

②The pump is a pre-standby type. If there is no improvement in the hard part such as, basically other

control will be in time. It may be used for evacuation, etc.

in the future prediction of inland water level inundation. Also, as the scale grows, the cost may become too high if

the construction is rushed, and the benefits may not be met. Conversely, if construction takes time, it

may be necessary to update the equipment that was originally completed.

|